Are Refuge Bays Life-Sustainable?

In the last 2 years, various mine fires occurred in collieries and hard rock mines where mining employees had to don their rescue packs and evacuate to Refuge Bays using Lifeline®. In some of these examples, employees were stuck underground for 24 hours before being rescued. These events continuously remind us that the life-sustainability of Refuge Bays is key to emergency preparedness of any mine and that emergency preparedness and response should be taken seriously.

Following these incidents, the need was identified for an independent assessment of the capability to sustain life inside underground Refuge Bays in South African Collieries.

The key question your Mine Leadership should contemplate is – are your Refuge Bays life-sustainable?

Coaltech was requested by the South African Colliery Managers Association (SACMA) to investigate and assess Refuge Bay life-sustainability. Rescue One reviewed this report and wants to highlight a few key thoughts and ideas that can help ensure your Refuge Bays are life-sustainable. This report can be downloaded from the Coaltech Website.

Who are we? Rescue One is the leader in emergency preparedness and response in South Africa. Following the issuing of the Coaltech report, we started a process of interviewing underground mine fire survivors. A report with best practices and recommendations on emergency preparedness and evacuation, with associated training material will be issued. Watch this space!

For now, here are a few observations from the report, some of which are only applicable to coal mines, but most are applicable to all mining industries:

1. A Refuge Bay on its own is not enough to save lives. Every mine needs a guidance rope system to get employees at risk to the Refuge Bay in zero visibility. Having Lifeline® installed correctly, used by mining personnel who are trained on using it and proficient in using Lifeline®, will assist in guiding them to a place of safety.

In our interviews with mine survivors who used Lifeline® to get to the Refuge Bay in zero visibility, they said, and I quote: ”If it was not for Lifeline®, we would not have made it”

2. Panic during an emergency can have disastrous effects. Both on the way to the Refuge Bay and once inside the Refuge Bay. Realistic emergency evacuation training in the form of rescue drills where self-contained self-rescuers (SCSR) are donned and Lifeline® is used to get to the Refuge Bay, is paramount to saving lives. Smoke machines can be used to make such training more realistic.

In our interviews with mine fire survivors, they indicated that some escapees could not don their SCSRs with confidence and needed help. In an emergency, time is of the essence, because once zero visibility is reached, donning a SCSR becomes very difficult and life-threatening if not done correctly and speedily.

3. Refuge Bay equipment such as the Refuge Bay Control Panel, lights, battery and siren must be in peak condition

and adequate for the size of your Refuge Bay and potential number of occupants. There are many factors raised in this report, but we would like to emphasize a few life-saving factors that should be considered:

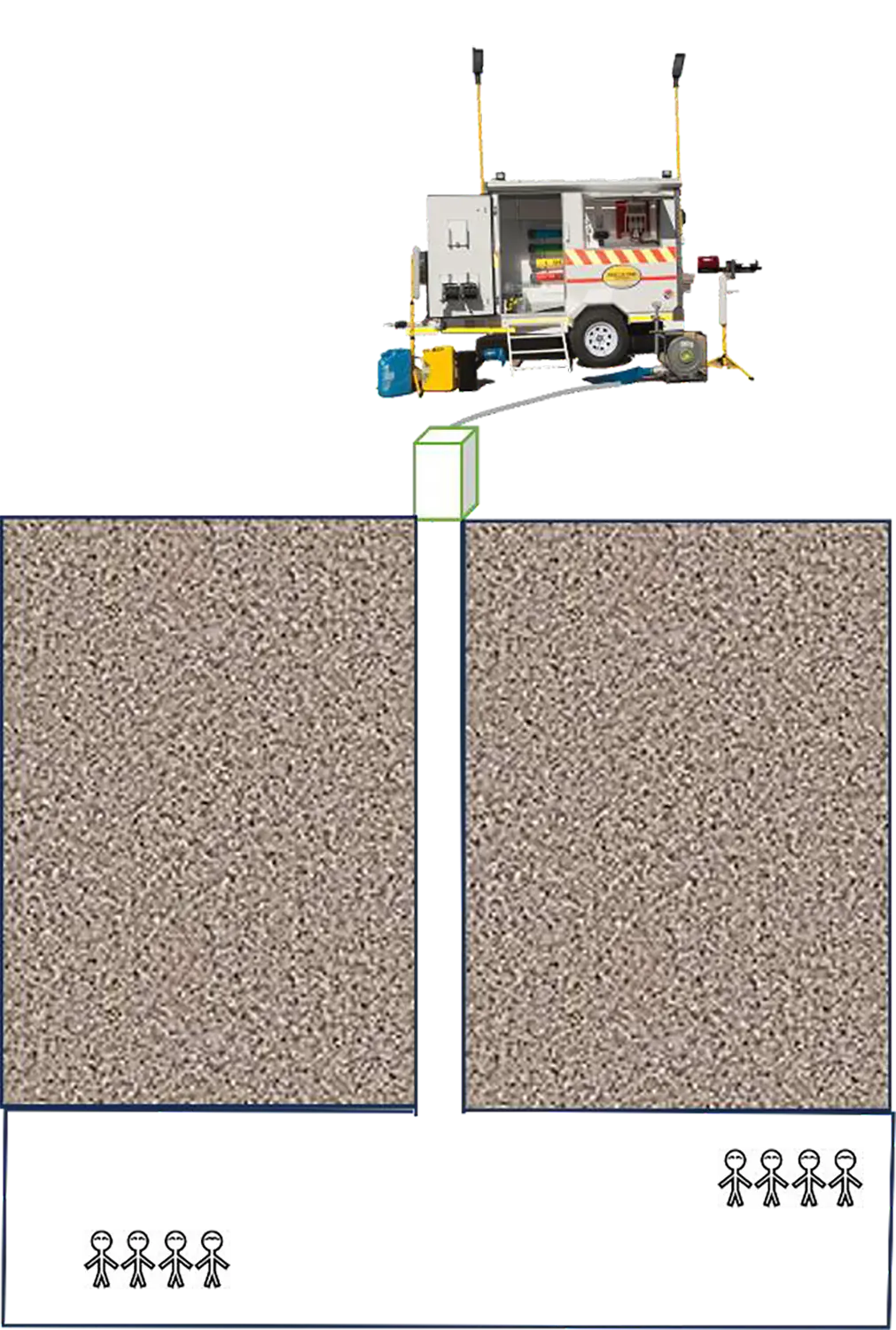

a. The Refuge Bay fan capacity to ventilate the refuge bay, given the size of the Refuge Bay and number of occupants. This goes for both the underground fan and the rescue trailer fan; if you have one. Rescue One’s Refuge Bay fan resulted in two air changes per hour, which sufficiently ventilated the refuge bay. As a Company, we decided to develop a fan with greater capacity that renders better results.

Rescue One’s trailer fan was also tested and was very effective at positively pressuring the Refuge Bay from surface. The rescue trailer fan needs to take into consideration the depth of the mine.

In the interviews we conducted, it was highlighted that one of the boreholes to the Refuge Bay was obstructed due to ground movement. It is crucial to monitor all boreholes to ensure they are accessible. The rescue teams also immediately deployed the rescue trailers on surface, which is a best practice. Waiting for the refuge bay backup battery to die before you deploy the trailers can have disastrous consequences. A real benefit of Rescue One’s refuge bay control panel is the digital display. It clearly shows the condition of the backup battery, which can empower miners with knowledge of how long they can survive in the refuge bay before surface ventilation is necessitated.

b. The Refuge Bay backup battery capacity and condition. The backup battery needs to be able to power the fan should the power go off, which is highly likely in the event of a fire. This gives rescue crews time to mobilise the rescue trailers in order to ventilate from surface through the borehole to the refuge bay. In one of the survivor interviews we conducted, some crews were stuck underground for 24 hours. This can be daunting for any person stuck underground or their families above ground who have no idea what is going on.

4. Having an early warning system such as the Rescue One fragrance system called Frontline®, can ensure that underground personnel evacuate in visibility and avoid getting trapped underground in zero visibility.

Rescue One holds the Patent and Trademark for this system in South Africa.

There were many more best practices captured in the Coaltech report that can be viewed on the Coaltech website. As Rescue One, we are passionate about Saving Lives.

We manufacture:

- Lifeline®, which is a directional rope guidance system that guides you to safety in zero visibility. We hold the Patent and Trademark for Lifeline® in South Africa.

- Refuge Bay Kits for Coal Mines.

- An early warning fragrance system called Frontline®, which we link to your existing smoke detectors. This system can prevent Miners from having to evacuate in zero visibility. We hold the Patent and Trademark for Frontline®

- S.O.S. – Support on Surface Rescue trailer for coal mines. We can customise this trailer for any mine’s requirements.

If you have any questions, contact us for more information.