About Us – Rescue One Equipment

Rescue One was established in 1996 with a view to developing products to eliminate unnecessary deaths due to the smoke inhalation in the Mining Industry in South Africa. We were requested by various top mining officials to develop systems whereby Miners could reach a place of safety, quickly, timelessly and alive. The Two main products developed are Lifeline and Frontline.

This article will give you an overview of Rescue One’s products and services:

Introduction

Underground Mine incidents such as fires can have dire consequences. First, the loss of life and second, infrastructure damage which leads to production and other losses. Prompt detection, timely and accurate warnings to those potentially affected, and a proficient response by underground mine workers can have a tremendous impact on the social and economic consequences of an underground fire.

In recent years we have seen a few disastrous incidents in South Africa:

- The underground fire at Palabora copper mine (2018) where 6 mine workers lost their lives

- The conveyor fire at Impala Platinum (2016) where four mine workers lost their lives; and;

- The underground fire at Harmony Gold (2015) where 486 mine workers were trapped underground before being rescued.

The Mine Health and Safety Act, 1996, section 2.1 (a) requires an employer to ensure that the mine is designed, constructed and equipped to provide conditions for safe operation and a healthy work environment and with a communication system and other equipment necessary to achieve those conditions. The Mine Health and Safety Inspectorate, 2011, requires a mandatory code of practice (COP) for emergency preparedness and response.

The Principal Inspector of Mines issued another directive in Limpopo on the 14th of February 2022 specifically relating to mine fires, explosions and emergency preparedness and response. This instruction emphasis and requires amongst others fire prevention controls which include guidelines surrounding:

- Risk assessment;

- Conveyor belt installation and management;

- Explosion prevention;

- Emergency preparedness which addressed:

- Early Fire Warning and detection systems;

- Firefighting systems; and

- Refuge Bays.

It is clear that the Department Mineral and Resources and Energy (DMRE) is serious about preventing fires and ultimately saving lives.

During the incipient stages of a fire, smoke and gaseous products (Sulphur dioxide (SO2) and carbon monoxide (CO)) are produced and released into the mine atmosphere. If these products are not detected in the early stages of combustion, they can result in severe hazards to personnel underground in the mine. Some underground mine fires are discovered in their early stages by mine personnel who see or smell smoke, then make a quick decision to either investigate and fight the fire or escape. Early detection of fires can save lives and prevent infrastructure damage. The challenge with early detection is the positioning of detectors and sensors relative to the ventilation flow of the mine.

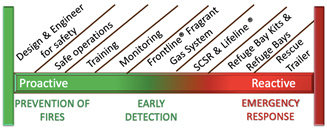

Figure 1 contains a graphic representation of the proposed emergency preparedness and response model that addresses both reactive and proactive measures. This model was also presented by Rescue One Equipment at the annual MVSSA Conference that was held in 2019.

Design and Engineer for Safety

First and foremost a mine should be designed and engineered with safety being a major factor. The design phase of a mine is the most appropriate time to influence safety and emergency preparedness and response controls. At this stage ventilation flow and the positioning of refuge bays and early detection and monitoring systems should be carefully considered. This includes the development of emergency evacuation routes and a COP for emergency preparedness and response, based on careful risk assessment as prescribed by the DMRE.

Safe Operations

Safely operating a mine is a fundamental principle. All procedures and COPs are to be adhered to. Management should put the necessary structures in place to ensure safe operations. It is important to note that working safe is also a mindset, as each mine worker has to take safety seriously and look out for him/herself, as well as for the welfare of fellow mine workers.

A major element of safety is looking after emergency response equipment on a daily basis. Should a mine worker walk past a defective emergency device, he/she should take the necessary steps to either report and or repair the device. Each mine worker should have a mindset to look after any equipment designed to save lives in event of an emergency such as a fire.

Training

Emergency preparedness and response training is one of the most important variables that can lead to safe evacuation in case of a fire. Biffi and Sehlabana (2018) quote research done by Bernich et al (1999). Forty-six mine workers were interviewed after escape experiences. Significant observations included:

- Mine workers admitted to panicking;

- Some mine workers admitted to not knowing what to do at the time;

- None of the mine workers had worn a SCSR prior to the emergency;

- Most mine workers indicated that they were not proficient in donning an SCSR;

- Some mine workers delayed donning their SCSR because they were aware of the limited duration of the unit;

- About 67% indicated they donned the SCSR in smoke; and,

- About 59% admitted to removing the mouthpiece or to breathing around it in smoke once the felt the resistance to breathing had become excessive.

Rescue One has developed emergency preparedness and evacuation training that is based on self-rescue principles. In other words, equipping underground mining personnel with the skills and confidence to get to a place of safety in the event of fire.

What is clear from the above is that psychological issues can have a significant impact. Effective emergency preparedness and response training can have a significant impact in removing a feeling of panic and uncertainty. A prerequisite is to implement such emergency evacuation training in a realistic setting. If you want to know more about the training we offer, please contact us on sales@rescueone.co.za.

Monitoring

Monitoring systems are essential for fire emergencies. The first step is implementing the right monitoring systems at the right places where fires are likely to occur such as conveyor belts.

Frontline® Fragrance Gas System

Early detection systems can play a major role in early evacuation once a fire has commenced and can help mine workers escape to a place of safety without having to don SCSRs or use Lifeline®.

Rescue One has implemented Frontline® (an early warning system that works on the same principle as a stench gas system) at various mines in South Africa with great success (such as Glencore and Kroondal). Frontline® is different from the typical stench gas systems as it releases a very strong grape or citrus fragrance in the intake, which is non-toxic. Research has shown that grape or citrus fragrance can be detected in smoke and depending on the ventilation flow in the mine, Frontline® could give mine workers 20-30 minutes head start to escape to a place of safety. The Frontline® units that are installed are linked to the existing gas detectors and when smoke, carbon monoxide or sulphur dioxide are detected, the Frontline® fragrance is released and allows early warning to underground mining personnel. This fragrance follows the flow of the ventilation in the mine. Smoke and CO Sensors are typically installed in areas where fires are likely to occur such as at conveyor belts, workshops and strategic positions in intake and return airways. The stronger your ventilation flow through your mine and working places the shorter the time it will take for the fragrant to reach the working places.

SCSR & Lifeline®

The deployment of SCSRs has been an integral part of emergency escape and rescue procedures from areas affected by irrespirable atmospheres. Lifeline® is operational in most coal mines. It has been proven to be the most effective method to help mine workers escape in zero visibility.

Historically Lifeline® has been predominantly used in the coal mines, but now has been successfully implemented in hard rock mines.

Refuge Bay Kits and Refuge Bays

A Refuge Bay is essential in the event of fire, as it provides a place of safety for mine workers to congregate until proto teams can rescue them. Appropriate and visible signage to refuge bays is critical. As smoke ascends, it is best to place signage at eye level or even slightly lower. Signage that is positioned too high would render no results in the event of a fire.

Refuge Bay control panels, lights, sirens and fans should at all times be in peak condition in the event of a fire. Rescue One supplies a refuge bay panel with digital displays that indicates life of battery and provides crucial information on how long the battery can continue powering the fan.

Rescue Trailer

In the event of mine workers being trapped for extended periods of time, a rescue trailer can significantly assist with the rescue mission. The Rescue Trailer is aimed at providing life sustaining support from surface in such emergencies. It is equipped with a bullet winch, fan, bullets, generators and emergency lighting. The content can be adjusted based on the type of mining at hand.

Using the bullets, food and first aid supplies or any other supplies that can help trapped mine workers in coal mines, as it can be lowered through the borehole into the refuge bay. The fan ensures a continuous supply of fresh air, which is powered by the generator that runs on diesel, hence providing a supply fresh air for as long as needed to the rescue bay. This, if required, provides mines in the event of an emergency with valuable time to find suitable alternatives to extract mine workers safely.

CONCLUSION

As per the directive from the DMRE, Limpopo, Mines should invest in both fit-for-purpose measures to support emergency preparedness and response, which can be both reactive and proactive such as early warning systems. Implementing early warning systems can save lives, equipment and infrastructure. It is imperative that mines apply the relevant control measures as contained in their COPs diligently and continuously ensure effective compliance to these requirements. At Rescue One we are committed to saving lives through the implementation of both early warning and reactive emergency response systems. If you wish to know more, contact us on sales@rescueone.co.za.

REFERENCES

Biffi, M. and Sehlabana. M. (2018). Self-Contained Self-Rescuer Training – Doing more with more. The Mine Ventilation Society of South Africa, 2018 Conference.

MORE ABOUT LIFELINE®

Lifeline was developed due to a number of mining accidents where miners lost their lives. They became disorientated, lost their way to the refuge bay and simply ran out of oxygen a few meters from safety. It is a scientific fact that people become disorientated in a smoke filled environment and can lose up to 40% of their senses; i.e. balance, hearing, sight, smell and taste. Therefore touch becomes important when attempting to escape in the conditions, especially if the senses are impaired.

In the aftermath of fires and explosions, smoke becomes a severe hindrance to the safe evacuation of mine personnel and greatly reduces the possibility of escape. It has been noted from incidents, both locally and internationally, that smoke which fills mine openings induces a “White out” and reduces visibility to almost zero.

In our development stages we carried out a number of escapes simulation test underground and found that without a rope guidance system, escape is virtually impossible in a underground emergency, due to either smoke, dust, and lack of normal guidance indicators. It is also a fact in thick smoke or dust, a person will lose many of his sensors, such as balance, sight and up to 50% of his hearing. Also in our tests where we blindfolded a number of experienced Miners and had them walk 250 meters in a straight passage without a Lifeline. This was an experience as 8 out of the 10 Miners veered off to their right and double backed on themselves and got totally lost. The others took over 20 minutes to cover the 250 meters. As Minors only have 30 minutes (under normal breathing conditions) of breathing time, this practise was unacceptable. The refuge bays are a 1000 meters away from the sections.

The results show that with the LIFELINE® Escape System, escape walking speed can be maintained. The average escape speed with LIFELINE® is 1.09m per second, representing a speed excess of 75% of that observed during normal conditions of visibility.

MORE ABOUT FRONTLINE®

Fires constitute an ever present hazard in the Mines. A fire can occur whenever combustible materials are present on Mine Workings. Underground fires not only endanger the valuable lives of Men, but also causes considerable economic losses to organisations affected by fires.

With the outburst of a fire underground, two important environmental issues occur, which present a grave danger to personnel underground and can effect lives of people in a matter of minutes.

The two conditions are SMOKE and CO. FRONTLINE® is an early warning detection system that will detect smoke/co from up to 1000m away from the section of the Mine where people are working.

The FRONTLINE® detection system is a revolutionary new concept in effective evacuation of Mines. The system releases a very powerful fragrance in the Intake Air Flow System of the Mine. The fragrance is atomised in the air flow and will travel along the intake airways at the same speed as the air flow. The fragrance will then enter the working section, warning people of smoke/co that is being detected up to 1000m away.

The principle behind FRONTLINE® is to eliminate the human factor of having to physically go into the section and warn people of approaching danger or when the section is already filled with smoke/co, safe evacuation then becomes very difficult. There is always a tremendous amount of noise in any Mine and hearing protection is worn by all Personnel, the chance of actually hearing a fire alarm is minimal.

By introducing a powerful fragrance, all Personnel will smell rather than hear of approaching danger and evacuate before the development of thick smoke which will reduce visibility to zero, where people become disorientated and lose their way to safety, FRONTLINE® (Smoke/Co Detection System) in conjunction with LIFELINE® Directional Rope Guidance System will provide each person that goes underground a safe and reliable evacuation system, which will enable persons in the case of an emergency to reach the Refuge Bay QUICKLY, SAFELY and ALIVE.